I-Thermal imaging embonini ye-fiber optic

IIkhamera ye-nfrared thermal isetshenziswa kabanzi, futhi imboni ye-fiber optic nayo ihlobene eduze ne-infraredisithombe esishisayo.

I-fiber laser inezinzuzo zekhwalithi enhle ye-beam, ukuminyana kwamandla aphezulu, ukusebenza kahle kokuguqulwa kwe-electro-optical, ukukhishwa okuhle kokushisa, ukwakheka okuhlangene, okunganakekelwa, ukudluliswa okuguquguqukayo, njll., futhi isiphenduke inkomba ejwayelekile yokuthuthukiswa kobuchwepheshe be-laser kanye amandla main isicelo. Ukusebenza kahle kwe-electro-optic jikelele kwe-fiber laser cishe ku-30% kuya ku-35%, futhi amandla amaningi alahleka ngesimo sokushisa.

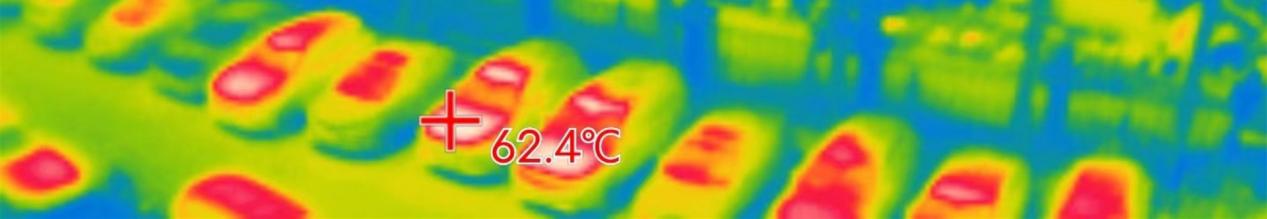

Ngakho-ke, ukulawulwa kwezinga lokushisa phakathi nenqubo yokusebenza ye-laser kunquma ngokuqondile ikhwalithi nempilo yesevisi ye-laser. Indlela yendabuko yokulinganisa izinga lokushisa lokuxhumana izocekela phansi ukwakheka komzimba we-laser, futhi indlela yokulinganisa izinga lokushisa okungelona iphuzu elilodwa ayikwazi ukuthwebula ngokunembile izinga lokushisa lefayibha. Ukusetshenziswa kwe-infraredikhamera eshisayoukuthola izinga lokushisa lama-fiber optical, ikakhulukazi amalunga okuhlanganisa ama-fiber optical, ngesikhathi senqubo yokukhiqiza ama-laser optical fiber angaqinisekisa ngempumelelo ukuthuthukiswa nokulawulwa kwekhwalithi yemikhiqizo ye-fiber optical. Ngesikhathi sokuhlolwa kokukhiqiza, izinga lokushisa lomthombo wepompo, isihlanganisi, i-pigtail, njll. kufanele likalwe ukuze kuqinisekiswe ikhwalithi yomkhiqizo.

Ukulinganisa izinga lokushisa lokucabanga okushisayo ohlangothini lohlelo lokusebenza kungabuye kusetshenziselwe ukulinganisa izinga lokushisa ku-laser welding, i-laser cladding nezinye izimo.

Izinzuzo eziyingqayizivele zekhamera ye-infrared thermal esetshenziswa ekutholeni i-fiber laser:

1. Ikhamera eshisayoinezici zokulinganisa izinga lokushisa lebanga elide, elingathinteki kanye nendawo enkulu.

2. Isofthiwe yezobuchwepheshe yokulinganisa izinga lokushisa, engakwazi ukukhetha ngokukhululekile indawo yokushisa yokuqapha, ithole ngokuzenzakalelayo futhi irekhode iphuzu eliphezulu lokushisa, futhi ithuthukise ukusebenza kahle kokuhlola.

3. Umkhawulo wezinga lokushisa, isampula lendawo engaguquki, nezilinganiso zokushisa eziningi zingasethwa ukuze kuqoqwe idatha okuzenzakalelayo nokukhiqizwa kwejika.

4. Sekela izinhlobo ezahlukene zama-alamu ashisa kakhulu izinga lokushisa, wahlulele ngokuzenzakalelayo izinto ezingalungile ngokwamanani abekiwe, futhi ukhiqize ngokuzenzakalelayo imibiko yedatha.

5. Sekela ukuthuthukiswa kwesibili kanye nezinsizakalo zobuchwepheshe, ukuhlinzeka nge-SDK yezingxenyekazi eziningi, futhi kube lula ukuhlanganiswa nokuthuthukiswa kwemishini ezishintshayo.

Enqubweni yokukhiqiza yama-laser e-fiber enamandla amakhulu, kungase kube nokunqamuka kokubona kanye nokukhubazeka kosayizi othile emalungeni e-fiber fusion. Ukukhubazeka okukhulu kuzodala ukushisa okungavamile kwamalunga e-fiber fusion, kubangele ukulimala kwe-laser noma izindawo ezishisayo ezishisayo. Ngakho-ke, ukuqapha izinga lokushisa kwe-fiber fusion splicing joints kuyisixhumanisi esibalulekile enqubweni yokukhiqiza ama-fiber lasers. Ukuqapha izinga lokushisa kwephoyinti lokuhlangana kwefayibha kungenziwa kusetshenziswa ikhamera eshisayo, ukuze kwahlulele ukuthi ikhwalithi yephuzu lokuhlanganisa i-fiber elilinganisiwe lifanelekile futhi lithuthukise ikhwalithi yomkhiqizo.

Ukusetshenziswa kwe-inthanethiikhamera eshisayoehlanganiswe kumishini ezishintshayo ingahlola izinga lokushisa lemicu yokubona ngokuzinzile futhi ngokushesha ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza.

Isikhathi sokuthumela: Feb-16-2023