I-Thermal Design Nokuphathwa

Ukushisa ngokweqile (ukukhuphuka kwezinga lokushisa) bekulokhu kuyisitha sokusebenza komkhiqizo ozinzile nothembekile. Lapho izisebenzi ze-R&D zokuphatha okushisayo zenza umboniso nomklamo womkhiqizo, zidinga ukunakekela izidingo zezinkampani ezihlukene zemakethe futhi zizuze ibhalansi engcono kakhulu phakathi kwezinkomba zokusebenza nezindleko eziphelele.

Ngoba izingxenye ze-elekthronikhi zithinteka ngokuyisisekelo ipharamitha yokushisa, njengomsindo oshisayo we-resistor, ukwehla kwe-PN junction voltage ye-transistor ngaphansi kwethonya lokushisa lokushisa, kanye nenani le-capacitance elingahambisani le-capacitor emazingeni okushisa aphezulu naphansi. .

Ngokusetshenziswa okuguquguqukayo kwamakhamera wesithombe esishisayo, izisebenzi ze-R&D zingathuthukisa kakhulu ukusebenza kahle kwazo zonke izici zedizayini yokukhipha ukushisa.

Ukuphatha okushisayo

1. Hlola ngokushesha umthwalo wokushisa

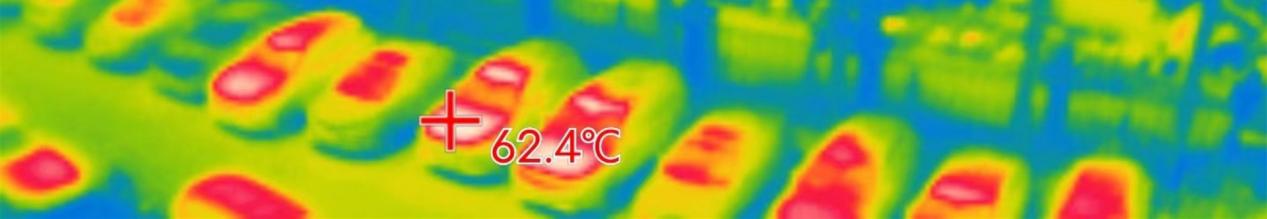

Ikhamera yesithombe esishisayo ingakwazi ukukubona ngeso lengqondo ukusatshalaliswa kwezinga lokushisa lomkhiqizo, isize abasebenzi be-R&D ukuthi bahlole ngokunembile ukusatshalaliswa kokushisa, bathole indawo enomthwalo wokushisa okweqile, futhi yenze idizayini elandelayo yokulahla ukushisa iqondiswe kakhulu.

Njengoba kuboniswe emfanekisweni ongezansi, okubomvu kusho ukuphakama kwezinga lokushisa..

▲Ibhodi le-PCB

2. Ukuhlolwa nokuqinisekiswa kohlelo lokususa ukushisa

Kuzoba nezinhlelo ezihlukahlukene zokukhipha ukushisa esigabeni sokuklama. Ikhamera yokuthwebula eshisayo ingasiza abasebenzi be-R&D ukuthi bahlole ngokushesha izikimu ezihlukene zokulahla ukushisa futhi banqume umzila wezobuchwepheshe.

Isibonelo, ukubeka umthombo wokushisa ohlukile kurediyetha yensimbi enkulu kuzokhiqiza ukuthambekela okukhulu okushisayo ngenxa yokuthi ukushisa kuhamba kancane kancane nge-aluminium kuya emaphikweni (amafins).

Izisebenzi ze-R&D zihlela ukufaka amapayipi okushisa kurediyetha ukuze kuncishiswe ukujiya kwepuleti likarediyetha nendawo yerediyetha, kuncishiswe ukuncika ekuxhumeni ngempoqo ukuze kuncishiswe umsindo, futhi kuqinisekiswe ukusebenza okuzinzile kwesikhathi eside komkhiqizo. Ikhamera yokuthwebula eshisayo ingaba usizo kakhulu konjiniyela bahlole ukusebenza kohlelo

Isithombe esingenhla siyachaza:

► Amandla omthombo wokushisa 150W;

►Isithombe sesokunxele: usinki wokushisa we-aluminium wendabuko, ubude obungu-30.5cm, ubukhulu besisekelo 1.5cm, isisindo esingu-4.4kg, kungatholakala ukuthi ukushisa kusakazwa kancane kancane nomthombo wokushisa njengesikhungo;

►Isithombe esingakwesokudla: I-sink yokushisa ngemuva kokufakwa kwamapayipi okushisa angu-5, ubude buyi-25.4cm, ubukhulu besisekelo bungu-0.7cm, kanti isisindo si-2.9kg.

Uma kuqhathaniswa ne-sink yendabuko yokushisa, impahla iyancipha ngo-34%. Kungatholakala ukuthi ipayipi yokushisa ingakwazi ukususa ukushisa kwe-isothermally kanye nokushisa kwe-radiator Ukusabalalisa kufana, futhi kutholakala ukuthi amapayipi okushisa angu-3 kuphela adingekayo ekuqhubeni ukushisa, okungase kunciphise nakakhulu izindleko.

Ngaphezu kwalokho, abasebenzi be-R&D badinga ukuklama isakhiwo kanye nokuxhumana komthombo wokushisa kanye nerediyetha yepayipi lokushisa. Ngosizo lwamakhamera we-infrared thermal imaging, abasebenzi be-R&D bathole ukuthi umthombo wokushisa nerediyetha ingasebenzisa amapayipi okushisa ukuze ibone ukuhlukaniswa nokudluliselwa kokushisa, okwenza idizayini yomkhiqizo ivumelane nezimo.

Isithombe esingenhla siyachaza:

► Amandla omthombo wokushisa angu-30W;

►Isithombe sesokunxele: Umthombo wokushisa uxhumene ngqo nosinki wokushisa wendabuko, futhi izinga lokushisa le-sink yokushisa liveza ukusabalalisa okusobala kwe-thermal gradient;

►Isithombe esingakwesokudla: Umthombo wokushisa uhlukanisa ukushisa kusinki yokushisa ngepayipi lokushisa. Kungatholakala ukuthi ipayipi lokushisa lidlulisela ukushisa kwe-isothermally, futhi izinga lokushisa lokushisa lisakazwa ngokulinganayo; izinga lokushisa ekugcineni elikude le-sink yokushisa liphakeme ngo-0.5 ° C kunomkhawulo oseduze, ngoba isitsha sokushisa sishisa umoya ozungezile Umoya uyakhuphuka futhi uqoqe futhi ushise ukuphela kwe-radiator;

► Abasebenzi be-R&D bangathuthukisa ngokwengeziwe idizayini yenombolo, usayizi, indawo, nokusatshalaliswa kwamapayipi okushisa.

Isikhathi sokuthumela: Dec-29-2021