Amakhono Okuhlola Asebenzayo

Ukuhlola okuphelele okusetshenziswa kukho konke ukuthuthukiswa komkhiqizo omusha konga imali yekhasimende kuyilapho kunciphisa isikhathi sokukhiqiza. Ezigabeni zokuqala, ukuhlolwa kwe-in-circuit, ukuhlola okuzenzakalelayo kwe-optical (AOI) kanye nokuhlolwa kwe-Agilent 5DX kunikeza impendulo ebalulekile eyenza kube lula ukulungisa okufika ngesikhathi. Bese kuthi ukuhlolwa okusebenzayo nokwesicelo kwenziwa ekucacisweni kwekhasimende ngalinye ngaphambi kokuthi ukuhlolwa okuqinile kwengcindezi yendawo kuqinisekise ukwethembeka komkhiqizo. Uma kuziwa ekwethuleni umkhiqizo omusha, i-POE suite yamakhono okusebenza nokuhlola iqinisekisa ukuthi uyakha kahle okokuqala ngqa, futhi iletha isisombululo esidlula okulindelekile.

Ukuhlola Okusebenzayo:

Isinyathelo Sokugcina Sokukhiqiza

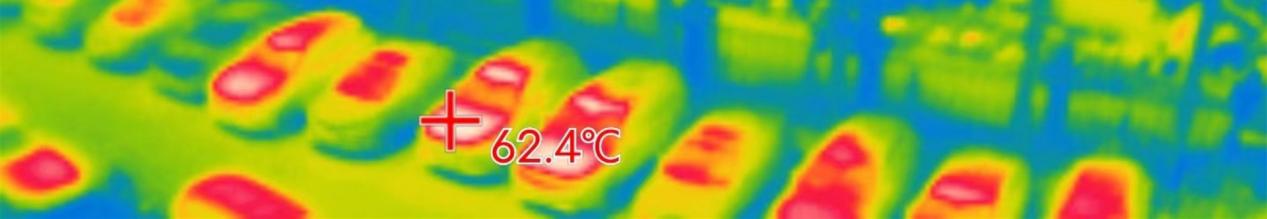

Ukuhlolwa okusebenzayo (i-FCT) isetshenziswa njengesinyathelo sokugcina sokukhiqiza. Inikeza ukudlula/ukwehluleka ukuzimisela kuma-PCB aqediwe ngaphambi kokuthi athunyelwe. Injongo ye-FCT ekukhiqizeni iwukuqinisekisa ukuthi ihadiwe yomkhiqizo ayinazo iziphazamiso ezingase, ngaphandle kwalokho, zibe nomthelela omubi ekusebenzeni okulungile komkhiqizo ohlelweni lokusebenza.

Ngamafuphi, i-FCT iqinisekisa ukusebenza kwe-PCB nokuziphatha kwayo. Kubalulekile ukugcizelela ukuthi izidingo zokuhlolwa okusebenzayo, ukuthuthukiswa kwayo, kanye nezinqubo ziyahluka kakhulu ukusuka ku-PCB kuye ku-PCB kanye nesistimu ngesistimu.

Abahloli abasebenzayo bavamise ukuxhumana ne-PCB ngaphansi kokuhlolwa ngesixhumi sayo sonqenqema noma iphoyinti lokuhlola. Lokhu kuhlola kulingisa indawo yokugcina kagesi lapho kuzosetshenziswa khona i-PCB.

Indlela ejwayelekile kakhulu yokuhlola ukusebenza ivele iqinisekise ukuthi i-PCB isebenza kahle. Ukuhlolwa kokusebenza okuyinkimbinkimbi okwengeziwe kubandakanya ukuhamba ngebhayisikili i-PCB ngokusebenzisa uhla oluphelele lokuhlolwa kokusebenza.

Izinzuzo Zekhasimende Zokuhlolwa Okusebenzayo:

● Ukuhlola okusebenzayo kulingisa indawo yokusebenza yomkhiqizo ovivinywayo ngaleyo ndlela kunciphisa izindleko ezibizayo zekhasimende ukuze linikeze okokusebenza kokuhlola kwangempela.

● Iqeda isidingo sokuhlolwa kwesistimu ezibizayo kwezinye izimo, okonga i-OEM isikhathi esiningi nezinsiza zezimali.

● Ingahlola ukusebenza komkhiqizo noma yikuphi ukusuka ku-50% ukuya ku-100% womkhiqizo othunyelwayo ngaleyo ndlela inciphise isikhathi nomzamo we-OEM ukuwuhlola nokuwususa.

● Onjiniyela bokuhlola abahlakaniphile bangakhipha ukukhiqiza okuningi ekuhlolweni kokusebenza ngaleyo ndlela bakwenze kube ithuluzi eliphumelela kakhulu ukushoda ekuhlolweni kwesistimu.

● Ukuhlola okusebenzayo kuthuthukisa ezinye izinhlobo zokuhlola ezifana ne-ICT nokuhlolwa kwe-flying probe, okwenza umkhiqizo ube namandla futhi ungabi namaphutha.

Ukuhlola okusebenzayo kulingisa noma kulingisa indawo yokusebenza yomkhiqizo ukuze kuhlolwe ukusebenza kwawo okulungile. Imvelo iqukethe noma iyiphi idivayisi exhumana nocingo oluvivinywayo (DUT), isibonelo, amandla e-DUT noma ukulayisha kohlelo oludingekayo ukuze i-DUT isebenze kahle.

I-PCB ingaphansi kokulandelana kwamasignali namandla kagesi. Izimpendulo zigadwa ezindaweni ezithile ukuze kuqinisekiswe ukuthi ukusebenza kulungile. Ukuhlola kuvamise ukwenziwa ngokuya ngonjiniyela wokuhlola we-OEM, ochaza imininingwane nezinqubo zokuhlola. Lokhu kuhlola kungcono kakhulu ekutholeni amanani engxenye engalungile, ukwehluleka kokusebenza kanye nokwehluleka kwepharamitha.

Isofthiwe yokuhlola, ngezinye izikhathi ebizwa ngokuthi i-firmware, ivumela abaqhubi bomugqa wokukhiqiza ukuthi benze ukuhlolwa okusebenzayo ngendlela ezenzakalelayo ngekhompyutha. Ukwenza lokhu, isofthiwe ixhumana nezinsimbi ezihlelekayo zangaphandle njenge-digital multi-meter, amabhodi e-I/O, izimbobo zokuxhumana. I-software ehlanganiswe ne-fixture exhumanisa izinsimbi ne-DUT yenza kube nokwenzeka ukwenza i-FCT.

Thembela Kumhlinzeki we-EMS we-Savvy

Ama-Smart OEMs athembele kumhlinzeki we-EMS ohloniphekile ukuthi afake ukuhlolwa njengengxenye yokwakheka nokuhlanganiswa komkhiqizo wawo. Inkampani ye-EMS yengeza ukuguquguquka okukhulu enqolobaneni yobuchwepheshe ye-OEM. Umhlinzeki we-EMS onolwazi uklama futhi ahlanganise uhla olubanzi lwemikhiqizo ye-PCB yeqembu lamakhasimende ahlukahlukene ngokulinganayo. Ngakho-ke, iqoqa arsenal ebanzi kakhulu yolwazi, isipiliyoni kanye nobuchule kunamakhasimende abo e-OEM.

Amakhasimende we-OEM angazuza kakhulu ngokusebenza nomhlinzeki we-EMS onolwazi. Isizathu esiyinhloko ukuthi umhlinzeki we-EMS onolwazi futhi onolwazi uthatha kusizinda sakhe sokuhlangenwe nakho futhi enze iziphakamiso ezibalulekile eziphathelene namasu namazinga ahlukene okuthembeka. Ngenxa yalokho, umhlinzeki we-EMS mhlawumbe usesimweni esingcono kakhulu sokusiza i-OEM ukuthi ihlole izinketho zayo zokuhlola futhi iphakamise izindlela zokuhlola ezingcono kakhulu zokuthuthukisa ukusebenza komkhiqizo, ukwenziwa komkhiqizo, ikhwalithi, ukwethembeka, kanye nezindleko ezibaluleke kakhulu.

I-flying head probe/ukuhlolwa okunganele kwe-fixture

I-AXI – 2D kanye nokuhlolwa kwe-X-ray okuzenzakalelayo kwe-3D

I-AOI – ukuhlola okuzenzakalelayo

I-ICT - ukuhlolwa kwe-in-circuit

I-ESS - ukuhlolwa kokucindezeleka kwemvelo

I-EVT - ukuhlolwa kokuqinisekiswa kwemvelo

I-FT - isivivinyo esisebenzayo nesistimu

I-CTO - lungiselela-uku-oda

Ukuhlaziywa kokuxilonga nokwehluleka

PCBA Manufacturing & Test

Ukukhiqizwa komkhiqizo wethu osuselwe ku-PCBA kusingatha izinhlobonhlobo zemihlangano, kusukela kumihlangano ye-PCB eyodwa kuya kuma-PCBA ahlanganiswe ezindaweni ezivalekile ezakhiwe ngamabhokisi.

I-SMT, i-PTH, ubuchwepheshe obuxubile

Iphimbo elihle kakhulu, QFP, BGA, μBGA, CBGA

Umhlangano we-SMT othuthukisiwe

Ukufakwa okuzenzakalelayo kwe-PTH (i-axial, i-radial, idiphu)

Akukho ukucubungula okuhlanzekile, okunamanzi nokungenamthofu

Ubuchwepheshe bokukhiqiza i-RF

Amandla enqubo ye-peripheral

Izindiza ze-Pressfit back nezindiza ezimaphakathi

Ukuhlelwa kwedivayisi

I-automatic conformal coating

Izinsizakalo Zethu Zobunjiniyela Benani (VES)

Izinsizakalo zobunjiniyela benani le-POE zinika amandla amakhasimende ethu ukuthi athuthukise ukwenziwa komkhiqizo nokusebenza kwekhwalithi. Sigxila kuzo zonke izici zokuklama nezinqubo zokukhiqiza - ukuhlola yonke imithelela ezindlekweni, emsebenzini, ohlelweni lohlelo kanye nezimfuneko zizonke.

I-ICT Yenza Ukuhlola Okuphelele

Ekuhlolweni kwesekethe (ICT) ngokwesiko isetshenziswa emikhiqizweni evuthiwe, ikakhulukazi ekukhiqizeni izinkontileka ezingaphansi. Isebenzisa uhlelo lokuhlola umbhede wezinzipho ukuze ifinyelele amaphuzu amaningi okuhlola ohlangothini olungezansi lwe-PCB. Ngamaphoyinti okufinyelela anele, i-ICT ingadlulisela amasignali okuhlola ukungena nokuphuma kuma-PCB ngesivinini esikhulu ukuze yenze ukuhlola kwezingxenye namasekhethi.

Isihloli sombhede wezinzipho siwuhlelo lokuhlola lwe-elekthronikhi lwendabuko. Inezikhonkwane eziningi ezishuthekwe emigodini, eqondaniswe kusetshenziswa izikhonkwane zokwakha

ukuthintana namaphoyinti okuhlola ebhodini lesifunda eliphrintiwe futhi axhunywe kuyunithi yokulinganisa ngezintambo. Lawa madivaysi aqukethe uxhaxha lwamaphinikhodi e-pogo amancane, alayishwe entwasahlobo athintana nenodi eyodwa kumjikelezo wedivayisi ehlolwayo (DUT).

Ngokucindezela i-DUT phansi phezu kombhede wezinzipho, ukuxhumana okuthembekile kungenziwa ngokushesha ngamakhulu futhi kwezinye izimo izinkulungwane zamaphuzu okuhlola ngamunye ngaphakathi kwesekhethi ye-DUT. Amadivayisi ahlolwe embhedeni wezihloli zezinzipho angase abonise umaki omncane noma i-dimple evela kumathiphu abukhali amaphini we-pogo asetshenziswe ku-fixture.

Kuthatha amaviki ambalwa ukwakha i-ICT fixture nokwenza izinhlelo zayo. I-fixture ingaba i-vacuum noma icindezele phansi. Ukulungiswa kwe-vacuum kunikeza ukufundwa kwesiginali engcono uma kuqhathaniswa nohlobo lokucindezela phansi. Ngakolunye uhlangothi, izinsimbi ze-vacuum ziyabiza ngenxa yobunkimbinkimbi bazo obukhulu bokukhiqiza. Umbhede wezinzipho noma umhloli we-in-circuit yiwona ovame kakhulu futhi odumile endaweni yokukhiqiza inkontileka.

I-ICT inikeza ikhasimende le-OEM izinzuzo ezifana nalezi:

● Nakuba kudingeka into ebizayo, i-ICT ifaka ukuhlolwa okungu-100% ukuze kutholakale wonke amandla nezikhindi eziphansi.

● Ukuhlolwa kwe-ICT kunika amandla ukuhlola futhi kuqede isidingo sokulungisa iphutha sekhasimende sibe cishe ku-ZERO.

● I-ICT ayithathi isikhathi eside kakhulu ukusebenza, isibonelo uma i-flying probe ithatha imizuzu engu-20 noma ngaphezulu, i-ICT ngesikhathi esifanayo ingathatha iminithi noma ngaphezulu.

● Ihlola futhi ibone izikhindi, ivuleke, izakhi ezingekho, izingxenye zenani ezingalungile, ukuhlukaniswa okungalungile, izingxenye ezikhubazekile nokuvuza kwamanje kumjikelezo.

● Ukuhlola okuthembeke kakhulu nokuphelele okubamba wonke amaphutha okukhiqiza, amaphutha edizayini, namaphutha.

● Inkundla yokuhlola iyatholakala ku-Windows kanye ne-UNIX, ngaleyo ndlela iyenze ibe indawo yonke kancane ezidingweni eziningi zokuhlola.

● Isixhumi esibonakalayo sokuthuthukiswa kokuhlolwa nendawo yokusebenza kusekelwe kumazinga esistimu evulekile enokuhlanganiswa okusheshayo kuzinqubo ezikhona zekhasimende le-OEM.

I-ICT iwuhlobo lokuhlola olukhathazayo kakhulu, olunzima, nolubizayo. Kodwa-ke, i-ICT ilungele imikhiqizo evuthiwe edinga ukukhiqizwa kwevolumu. Isebenzisa isignali yamandla ukuhlola amazinga kagesi nezilinganiso zokumelana kumanodi ahlukene ebhodi. I-ICT inhle kakhulu ekutholeni ukwehluleka kwepharamethri, amaphutha ahlobene nomklamo kanye nokwehluleka kwengxenye.

Isikhathi sokuthumela: Jul-19-2021